The wood that is transformed into a Steinway model D is of several different kinds, each with its own characteristics and purposes. Yellow poplar, which is soft and relatively cheap, is used as the “core wood” of such fiat, tablelike parts as the piano’s top; it is veneered with mahogany to give an attractive appearance. Maple is used where extreme hardness is necessary–for example, in the pin block, also called the wrest plank, which must hold the tuning pins tight against the tension of the strings, and in the action, whose hundreds of tiny moving parts must be machined to precise tolerances. Sitka spruce, light in weight and high in strength, is used for structural cross braces; also, because it has long, parallel fibers that vibrate freely, it is used in the soundboard, the thin panel inside the case that amplifies the vibrations of the strings and projects their sound into the air.

The wood that is transformed into a Steinway model D is of several different kinds, each with its own characteristics and purposes. Yellow poplar, which is soft and relatively cheap, is used as the “core wood” of such fiat, tablelike parts as the piano’s top; it is veneered with mahogany to give an attractive appearance. Maple is used where extreme hardness is necessary–for example, in the pin block, also called the wrest plank, which must hold the tuning pins tight against the tension of the strings, and in the action, whose hundreds of tiny moving parts must be machined to precise tolerances. Sitka spruce, light in weight and high in strength, is used for structural cross braces; also, because it has long, parallel fibers that vibrate freely, it is used in the soundboard, the thin panel inside the case that amplifies the vibrations of the strings and projects their sound into the air.

Before these woods can begin their year-long journey through the factory, they must wait outside, drying and curing, for nine months or more. Warren Albrecht, Steinway’s lumber buyer and wood technologist, told me that some of the lumber arriving in the yard is actually up to 80 percent water. The water has to go. Wood expands and contracts as it takes on and loses moisture; before being fashioned into parts that will fit together, it must be dried to a water content of about 6 percent, to minimize the possible changes in dimension. Breathing the New York air for several months is the first of two drying steps; despite rain and snow this reduces the wood’s water content to about 25 percent. Wringing out the remainder usually requires several weeks of kiln drying, in cavernous rooms where temperatures of up to 160 degrees Fahrenheit shrink the lumber to about nine-tenths of its original volume. I asked Albrecht to take me into one of the kilns, but found standing for a few seconds at the open door of one quite sufficient to satisfy my curiosity.

After drying, the wood goes to the crosscut department, on the first floor of the factory, to be prepared for the woodworkers. Here the discolored surfaces are planed away–the wood looks new again. Boards are cut to convenient lengths according to their destinies, and all sections containing knots and other intolerable imperfections are thrown on the scrap heap. Another third of the lumber’s original volume is lost in this way. Along with the cuttings, shavings, and sawdust produced elsewhere in the factory, the scrap goes into a wood- burning boiler that supplements the plant’s conventional oil furnace. All told, as much as 60 percent of the lumber Steinway buys either evaporates or goes up in smoke. The rest goes into pianos.

After drying, the wood goes to the crosscut department, on the first floor of the factory, to be prepared for the woodworkers. Here the discolored surfaces are planed away–the wood looks new again. Boards are cut to convenient lengths according to their destinies, and all sections containing knots and other intolerable imperfections are thrown on the scrap heap. Another third of the lumber’s original volume is lost in this way. Along with the cuttings, shavings, and sawdust produced elsewhere in the factory, the scrap goes into a wood- burning boiler that supplements the plant’s conventional oil furnace. All told, as much as 60 percent of the lumber Steinway buys either evaporates or goes up in smoke. The rest goes into pianos.

In various departments on the first and second floors of the factory, the wood is transformed from boards into rough approximations of piano parts. A naif in the ways of woodworking, I found in these departments the answers to questions I had never thought of asking. For example: Given that maple trees grow up and down, as a rule, how does one obtain the curvaceous contours of a grand piano’s rim? If the top of a piano measures roughly sixty inches at its widest point, does one need a five-foot-thick poplar tree to make it? If birch, the wood from which piano legs are carved, is generally available in the form of boards no more than three inches thick, whence come the blocky chunks of wood with which the carvers start?

In a word, the answer to these questions is glue. The block from which a model-D leg is carved is made of two pieces of birch glued together. The large sheet of poplar that becomes a top is simply fifteen to twenty boards glued together along their lengths. Much of the gluing is done on gangly “glue wheels,” which look vaguely like giant metal Rolodexes; their “cards,” a dozen or so per wheel, are clamp assemblies that hold the pieces of wood in place while the glue sets. The blocks and panels that result are slapdash–irregularly shaped, and patterned with streams of hardened excess glue–but when they have been planed and sanded the seams virtually disappear, and the pieces look almost as if they had been cut whole from oversize trees.

Having heard comments around the factory about the difficulty of obtaining wood in convenient sizes, I asked Warren Albrecht if this gluing of blocks and panels was a traditional woodworking practice or a new one made necessary by the limited sizes in which lumber is available today. He answered that it was a little bit of both. “We don’t have the selection of trees we used to have, because trees of the quality we need take, let’s say, a hundred years to grow to full size; they don’t grow them to full size anymore. So the boards are getting narrower, and we probably have to put more boards in a panel than we used to. But woodworkers have pretty much always glued up panels. The concept itself, I guess, has been around for the entire history of the piano. You have to do it, for certain items.”

Albrecht went on to correct the mistaken assumption implied in my question: that a built-up block or panel is weaker, less stable, or somehow inferior to a piece of wood cut solid from a log. “The glue is stronger than the wood,” he said. “If you do a proper job of gluing a panel and then try to break that panel, you’ll find the wood is going to break rather than the glue joint. Gluing also helps because any one board might have a tendency to, say, shrink or swell more than another board. By putting boards of varying characteristics together, you can compensate. You’ll get an overall average of stability”

The most difficult gluing job in the creation of a Steinway–and the most spectacular, a favorite on the factory visitors’ tour–is the construction of the rim. Actually there are two rims: the outer rim, the piano’s exterior wall; and the inner rim, a shallower interior wall that forms a ledge to which the cast-iron plate and the soundboard are attached. Most piano makers build the two rims separately: they make the inner rim first, build the piano’s works onto it, and then glue the outer rim around it. Steinway builds the inner and outer rims together, as a single piece, which makes for stronger, more integral construction, perhaps a better sound, and certainly a lot more work.

The rim begins as quarter-inch-thick slats of maple, which arrive at the lumberyard in various lengths and widths, none of them appropriate to the task. Some of the slats must be “paneled,” or glued along their lengths, to a width of about twelve and one-half inches–the approximate depth of the model D’s outer rim. Others must be “ripped,” or sawed along their lengths, to about half that width-the inner rim. Boards of like width are glued and tongue- jointed to a length of twenty-two feet, which is roughly the measure of the piano’s perimeter from the bass side around to the treble. (There is no left and right in a piano factory, only bass and treble.) Typically a “book” of boards–one rim’s worth–consists of nine narrow maple boards, five wider ones, and four layers of other types added for strength and decoration. At this point the rim wood is about 10 percent water instead of the usual 6. The extra moisture is needed for pliability because the eighteen layers of wood, some three and one-half inches thick in all, are about to be coerced–bent, shoved, and grunted over–into the impossible curves that make up the shape of a grand piano. Not one at a time, but all at once.

This happens in a large basement room where eight massive piano- shaped forms of steel, their perimeters fitted with gargantuan screws and clamps, stand along two walls almost like instruments in a showroom. These are rim-bending presses, the tools of the maple’s fate. The model-D press goes into service most mornings at 9:45, when the rim-department crew returns from its coffee break. As a special precaution–one of many taken throughout the factory for the model D– one man stays behind at break time to mix a new batch of urea-resin glue, which is most effective when it is fresh. This is done because the D rim is the largest Steinway makes–and therefore the most susceptible to failure–and because the model D is the flagship of the Steinway line. Not that it happens, but if the rim of a baby grand model S were to spring apart at the seams one day, it would most likely be in the living room of a kindly old music teacher somewhere in the Midwest; if a model D were to come unglued, it might be on the stage of Carnegie Hall.

The crew of six, some with glue buckets, rags, and brushes in hand, line up in single file along a narrow bench about two feet high. At one end of this bench is an automatic glue applicator, a wringer-like machine through which the department’s foreman, Ralph D’Alleva, feeds the wooden layers one at a time. The long boards have been scored on both sides to give the best possible gluing surface. They have also been arranged so that the “inside” of one board–the side that grew closest to the center of the tree–faces the “outside” of the next; each layer will thus counteract the warping tendency of its neighbor. As each board emerges from the gluing machine, the workers line it up on the bench. Some spread glue over spots the machine has missed, and one cleans excess glue with a wet rag. D’Alleva yells “Glue!” and a man appears at his side with a bucket, emptying it into the machine. The work is hurried. Once the glue is applied, the crew has twenty minutes to get the wood clamped into the press. In the old days, when they used hot glue made from animal matter, they had even less time.

Within a few minutes, the “book” has been assembled and aligned on the bench, the wider layers of the outer rim on top. Now the crewmen, protecting their hands with thick sheets of sandpaper, lift the heavy mass of wood and struggle hurriedly with it to the press. Starting at the front, or keyboard end, of the piano, they lay and clamp the book first along the straight bass side of the press–the easy part. Next, however, comes an extremely difficult part, the virtual ninety-degree bend at the back. D’Alleva says, “All right, start movin’,” and there follows a flurry of heaving, shoving, and pulling against the wood’s desire to remain straight. A few men apply clamps and tighten screws with T-bars bigger than tire irons. Another evens the layers with a block of wood, setting it against their edges and pounding it from above with a large hammer. The block he uses is itself a section cut from an old laminated rim–a reminder, perhaps, that this crazy process will really work, that the wood will stay in place once the glue dries.

The wood’s resistance increases as the men wrap it around to the treble side of the press. One of the crew takes up a wooden lever about five feet tall, shaped roughly like a lowercase letter b, and, as a couple of others pull the last section of rim into place with a block and tackle, he and a few mates apply the bulbous end of the lever against the wood and press it into the graceful curve near the front of the piano. They look remarkably like the Marines who raised the flag over Iwo Jima. “Push!” “Get it!” “Once more. . . .

“Okay!” Suddenly, the frenzy subsides. The rebellious wood is locked safely in the press. A couple of crewmen casually tighten clamps, and the rest walk off to their next task.

The rim of K 2571 was bent in this fashion on February 6, 1981. The next workday, it was removed from the press, upended, and ten weeks placed in a brace that kept its ends from flying out. It spent in the humidity-controlled rim-bending room, during which time the maple’s water content was slowly reduced to about 6 percent. By then, the wood had “forgotten” its original shape. In April, it was taken to the frazing department, where workers sawed, planed, and sanded it to specifications, and from there it went to the case- making department, where cross braces, a key bed, and a pin block were installed. Now a “case” instead of a “rim,” it went in June to the lacquer department, where, except for very rare special orders, each model D receives five coats of functional, basic black.

At about the same time the lacquering began on the fourth floor of the factory, a soundboard and a cast-iron plate were taking shape on the first and second floors. The soundboard’s function is to amplify the sound of a slender string into a sound capable of filling a concert hall, and every detail of its construction is aimed at maximizing its ability to vibrate. The wood is an expensive grade of Sitka spruce, with no fewer than ten grains, or growth rings, per inch. It is sawed from the log so that its grain lines–and thus its vibrating fibers-run straight along the length of each board. The soundboard panel, made of about twenty boards glued together along their lengths, is thinned in places, like the face of a fine violin, to encourage movement. Finally, and most important, the board is made to bow out slightly in the center: the bridge, the long, snaky strip of laminated maple on which the strings will rest, is affixed to the top of the panel, and ribs are affixed to the underside, such that the board is distorted into a slight crown, increasing its ability to project sound waves into the air.

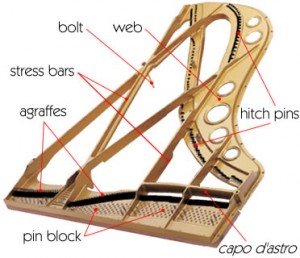

The cast-iron plate, made by the Wickham Piano Plate Company, of Springfield, Ohio, arrived at the factory an intricately shaped but roughly finished hunk of dull gray metal. Workers in the plate department, on the first floor of the factory, ground down its rough edges, smoothed its surface, painted it gold, and buffed it to a soft, brassy luster. Also, with the guidance of templates prepared and maintained by the engineering department–“patterns,” they are called–they installed the pieces that would later determine the crucial placement of the strings: the agraffes, the guideposts through which the strings emerge at the front of the piano, and the hitch pins, around which they loop in the back.

The cast-iron plate embodies the two major design elements that propelled Steinway & Sons to the top of the piano business in the mid- 1800s. One of these elements was the use of the plate itself, which permitted much higher string tension than could be borne by pianos made entirely of wood or of wood fortified with metal bars. The added strength allowed the use of bigger–and thus louder–strings. The second design element was the piano’s “scale,” which is essentially the arrangement of its strings–their vibrating lengths, their placement on the bridge, and the point at which they are struck by the hammers.

The cast-iron plate embodies the two major design elements that propelled Steinway & Sons to the top of the piano business in the mid- 1800s. One of these elements was the use of the plate itself, which permitted much higher string tension than could be borne by pianos made entirely of wood or of wood fortified with metal bars. The added strength allowed the use of bigger–and thus louder–strings. The second design element was the piano’s “scale,” which is essentially the arrangement of its strings–their vibrating lengths, their placement on the bridge, and the point at which they are struck by the hammers.

The most important feature of the new Steinway scale was the “overstringing” technique, in which the bass strings, instead of running parallel to the others, are fanned over them diagonally in a second tier of strings; this permitted longer bass strings and, again, more volume. Neither of these design elements was radical: overstringing had been used in square pianos since the 1830s; the metal plate had been developed by the Boston piano maker Alpheus Babcock in the 1820s, and Jonas Chickering, also of Boston– the foremost American piano maker before the Steinways came along– had been using it in his grand pianos since the 1840s. The Steinways’ masterstroke was to combine the two ideas in a new design, which also included heavier hammers to excite the heavier strings, a subtly improved action to permit control of the heavier hammers, and a repositioning of the bridge from the rear of the soundboard toward the middle.

The most important feature of the new Steinway scale was the “overstringing” technique, in which the bass strings, instead of running parallel to the others, are fanned over them diagonally in a second tier of strings; this permitted longer bass strings and, again, more volume. Neither of these design elements was radical: overstringing had been used in square pianos since the 1830s; the metal plate had been developed by the Boston piano maker Alpheus Babcock in the 1820s, and Jonas Chickering, also of Boston– the foremost American piano maker before the Steinways came along– had been using it in his grand pianos since the 1840s. The Steinways’ masterstroke was to combine the two ideas in a new design, which also included heavier hammers to excite the heavier strings, a subtly improved action to permit control of the heavier hammers, and a repositioning of the bridge from the rear of the soundboard toward the middle.

The result was an instrument unlike any heard before. Hector Berlioz, encountering the Steinway at the international exposition of Paris in 1867, remarked not only on its “splendid and noble sonority” but on the ingenuity of its scaling, which subdued the “terrible resonance of the minor seventh,” an undesirable overtone occasionally heard from other pianos of the time. The exposition’s jurors were likewise impressed: even though none of them was an American (patriotism was often an important factor in these international trade shows), they awarded the Steinway their gold medal. Within a few years, the prestigious old piano houses of Europe were fading into obscurity, and the rest of the industry was quickly adopting what had come to be called the “American system” or “Steinway system” of piano design. Those terms are not used much today, because today there is no other system.

Source: http://www.sherwinbeach.com