Steinway’s manufacturing methods are careful and traditional, but they are not primitive. In the rim-bending room, where a century ago the use of hot animal glue required that grand- piano rims remain locked in their presses for the better part of a day or more, synthetic glue is now cured by high-frequency heating, allowing most rims to be removed in little more than an hour. (The high-frequency curing is not necessary in the case of the model D, which is produced at a rate of fewer than 200 a year.) In the plate department, which once ran chiefly on steam power and elbow grease, paint sprayers and electric grinders abound. Where the soundboards of old were shaped by patient craftsmen with hand planes, giant planing and sanding machines now do the job automatically.

Steinway’s manufacturing methods are careful and traditional, but they are not primitive. In the rim-bending room, where a century ago the use of hot animal glue required that grand- piano rims remain locked in their presses for the better part of a day or more, synthetic glue is now cured by high-frequency heating, allowing most rims to be removed in little more than an hour. (The high-frequency curing is not necessary in the case of the model D, which is produced at a rate of fewer than 200 a year.) In the plate department, which once ran chiefly on steam power and elbow grease, paint sprayers and electric grinders abound. Where the soundboards of old were shaped by patient craftsmen with hand planes, giant planing and sanding machines now do the job automatically.

This modernization, however, has been confined largely to the areas where individual parts are made. On the third and fourth floors of the factory, where the parts begin coming together for assembly, the machines and up-to-the-minute industrial techniques fade into the background. To a remarkable extent, Steinway has eschewed the assumption that piano pieces can be made to specifications and fitted together interchangeably. It is much more common for parts to be built originally to excess dimensions, so that they can be painstakingly matched one to the other by the same means used in the 1800s–human hands, eyes, and sweat.

The fourth floor of the factory is the home of the “belly” department, which performs one of the first, and one of the most critical, in a long line of custom-fitting operations. The title of the job’s description makes it seem a rather simple affair–to fit and glue a soundboard into the case–but it actually involves the installation of several ancillary parts and takes roughly eight hours, usually over the course of two days. The bellyman who worked on K 2571 was Valentine Toussaint, an immigrant from the Caribbean island of Saint Kitts, and he was something to see. A lithe, muscular man of thirty-four, wearing a rugged leather apron to protect his trousers and a headband to keep the sweat out of his eyes, he stalked the perimeter of the piano with the single-mindedness of a man possessed. Like most Steinway hands, he is paid for speed, on a piece- work basis. More than most, however, he obviously comes to the factory to make money. At one point well into the job, he opened a locker, popped a few pieces of candy into his mouth, and announced that he was taking a break. He was back at work before three minutes had passed. The job comprised long sequences of minute, interdependent steps, and, because it involved considerable gluing, he worked on two pianos at once, moving to one as the glue set on the other. Despite this, he never had to pause to consider his next move. The tools he needed always seemed to be right at his fingertips. His drill always seemed to have the right bit in it. Joe Pramberger, Steinway’s vice president in charge of manufacturing, passed Toussaint’s “station” on a walk through the factory and stopped for a moment to watch. “Look at him,” Pramberger said in a low tone of admiration, “he doesn’t waste a move.” Pramberger pointed out a long row of cubbyholes, each containing one tool, on a workbench behind Toussaint. “See those tools he’s got back there? Move one of them and you’d throw his whole routine off.”

The fourth floor of the factory is the home of the “belly” department, which performs one of the first, and one of the most critical, in a long line of custom-fitting operations. The title of the job’s description makes it seem a rather simple affair–to fit and glue a soundboard into the case–but it actually involves the installation of several ancillary parts and takes roughly eight hours, usually over the course of two days. The bellyman who worked on K 2571 was Valentine Toussaint, an immigrant from the Caribbean island of Saint Kitts, and he was something to see. A lithe, muscular man of thirty-four, wearing a rugged leather apron to protect his trousers and a headband to keep the sweat out of his eyes, he stalked the perimeter of the piano with the single-mindedness of a man possessed. Like most Steinway hands, he is paid for speed, on a piece- work basis. More than most, however, he obviously comes to the factory to make money. At one point well into the job, he opened a locker, popped a few pieces of candy into his mouth, and announced that he was taking a break. He was back at work before three minutes had passed. The job comprised long sequences of minute, interdependent steps, and, because it involved considerable gluing, he worked on two pianos at once, moving to one as the glue set on the other. Despite this, he never had to pause to consider his next move. The tools he needed always seemed to be right at his fingertips. His drill always seemed to have the right bit in it. Joe Pramberger, Steinway’s vice president in charge of manufacturing, passed Toussaint’s “station” on a walk through the factory and stopped for a moment to watch. “Look at him,” Pramberger said in a low tone of admiration, “he doesn’t waste a move.” Pramberger pointed out a long row of cubbyholes, each containing one tool, on a workbench behind Toussaint. “See those tools he’s got back there? Move one of them and you’d throw his whole routine off.”

He was fast, but not hasty. The cast-iron plate, which had been fitted to the case the day before, was now suspended from a ceiling- mounted winch, and Toussaint must have raised and lowered it at least half-a-dozen times in the course of the job, each time making certain measurements, placing certain parts. For a while I wondered why he didn’t make all the necessary measurements and guide marks at once– wouldn’t that be faster?–but I learned that the repetitiveness is an essential part of the custom-fitting process. He had to adjust the height of the bridge, but he couldn’t do that until he knew how the soundboard would sit in the piano’s case. He couldn’t know how the soundboard would sit until he had prepared and installed the rail to which it would be glued at the front of the case. He couldn’t know exactly where the front rail would go until he had planed the soundboard to fit the back of the case. Patterns helped him to place the pieces, but the patterns merely represented a design; Toussaint was working on a piano.

He was fast, but not hasty. The cast-iron plate, which had been fitted to the case the day before, was now suspended from a ceiling- mounted winch, and Toussaint must have raised and lowered it at least half-a-dozen times in the course of the job, each time making certain measurements, placing certain parts. For a while I wondered why he didn’t make all the necessary measurements and guide marks at once– wouldn’t that be faster?–but I learned that the repetitiveness is an essential part of the custom-fitting process. He had to adjust the height of the bridge, but he couldn’t do that until he knew how the soundboard would sit in the piano’s case. He couldn’t know how the soundboard would sit until he had prepared and installed the rail to which it would be glued at the front of the case. He couldn’t know exactly where the front rail would go until he had planed the soundboard to fit the back of the case. Patterns helped him to place the pieces, but the patterns merely represented a design; Toussaint was working on a piano.

Determining the height of the bridge–or “taking the bearing” as it’s called at Steinway–was the most critical part of Toussaint’s job. In the finished piano, the bridge extends upward from the soundboard through cutout sections of the cast-iron plate above, meeting the strings at a point slightly higher than the top of the plate. For the strings effectively to transmit their vibrations to the bridge, which in turn transmits them to the soundboard, they must bear down on it with a force of between 600 and 900 pounds. Too little pressure, and the piano will sound weak; too much, and it will sound muffled. Because the position of the plate, and thus the height of the strings, has been determined at this stage, the height of the bridge must be adjusted, by planing, to result in the proper pressure. The bridge is built originally to excess height and capped with a layer of easily planed wood to make this adjustment possible.

To take the bearing, Toussaint arranged the soundboard and plate in the case as they would fit when glued and bolted in permanently, then produced a small wooden box from which he took a few lengths of green string and several “bearing blocks”–thin rectangular pieces of metal, smaller than postage stamps, each marked with its thickness. He ran one of the green strings through an agraffe, across the bridge, and back to the rear of the plate–as though it were a true piano string. He placed a one-millimeter-thick bearing block on the plate and held the string down on it with his finger. The string thus rose from the agraffe to the bridge, and from there descended to a point one millimeter above the surface of the plate. Toussaint’s object was to adjust the bridge so there would be no rise and no descent. Later, when the piano was strung with wire and no bearing blocks, this would give just the right amount of rise and descent– the right amount of pressure.

To take the bearing, Toussaint arranged the soundboard and plate in the case as they would fit when glued and bolted in permanently, then produced a small wooden box from which he took a few lengths of green string and several “bearing blocks”–thin rectangular pieces of metal, smaller than postage stamps, each marked with its thickness. He ran one of the green strings through an agraffe, across the bridge, and back to the rear of the plate–as though it were a true piano string. He placed a one-millimeter-thick bearing block on the plate and held the string down on it with his finger. The string thus rose from the agraffe to the bridge, and from there descended to a point one millimeter above the surface of the plate. Toussaint’s object was to adjust the bridge so there would be no rise and no descent. Later, when the piano was strung with wire and no bearing blocks, this would give just the right amount of rise and descent– the right amount of pressure.

With a thick handsaw; Toussaint made a shallow gash in the bridge’s cap, passed the string through it, peered at the string, wiggled it around a little, and deepened the gash, continuing in this fashion until he was satisfied that the string was just resting on the bottom of the gash, with no upward or downward deflection. Then he blackened the bottom of the gash with a lead pencil. After performing this operation with different-sized bearing blocks at fourteen different “notes,” from the bass side to the treble, he had fourteen black gashes on the bridge. He hoisted the plate, removed the soundboard, and hand-planed the bridge until the pencil marks just disappeared. Presumably the bridge was now precisely the right height.

Plenty of work remained, however, before Toussaint would know for sure. He drilled holes in the bridge for the bridge pins that would guide the strings across it. He painted the top of the bridge with lubricating black graphite, then chiseled notches in it, by hand, so that each string would come in contact with only a carefully defined section of wood. He hammered the copper-colored bridge pins in, 486 of them, again by hand, and filed down their tops–twice. About two hours after taking the bearing, he was ready to glue the soundboard to the top of the inner rim. He lifted the board out of the piano and placed it in a “steam box”–a heated locker–a few yards from his station. He closed the window behind him, and, without any signal that was apparent to me, the man at the next station closed his window and appeared at Toussaint’s side with a glue bucket in hand. Hastily the two brushed hot animal glue onto the inner rim. The glue, which is useless once it begins to cool, was the reason for the haste, for the steam box, and for the closed windows–even though it was August. When Toussaint set his brush down and hurried to the steam box for the soundboard, two more workers materialized, one of them dragging a cart holding more than forty large C clamps. Toussaint slapped the board into place, and all began clamping and tightening. When it was done, no more than a couple of minutes later, the helpers disappeared as quickly as they had come.

Plenty of work remained, however, before Toussaint would know for sure. He drilled holes in the bridge for the bridge pins that would guide the strings across it. He painted the top of the bridge with lubricating black graphite, then chiseled notches in it, by hand, so that each string would come in contact with only a carefully defined section of wood. He hammered the copper-colored bridge pins in, 486 of them, again by hand, and filed down their tops–twice. About two hours after taking the bearing, he was ready to glue the soundboard to the top of the inner rim. He lifted the board out of the piano and placed it in a “steam box”–a heated locker–a few yards from his station. He closed the window behind him, and, without any signal that was apparent to me, the man at the next station closed his window and appeared at Toussaint’s side with a glue bucket in hand. Hastily the two brushed hot animal glue onto the inner rim. The glue, which is useless once it begins to cool, was the reason for the haste, for the steam box, and for the closed windows–even though it was August. When Toussaint set his brush down and hurried to the steam box for the soundboard, two more workers materialized, one of them dragging a cart holding more than forty large C clamps. Toussaint slapped the board into place, and all began clamping and tightening. When it was done, no more than a couple of minutes later, the helpers disappeared as quickly as they had come.

The glue was allowed to set for several hours. After removing the clamps and performing a few final tasks, Toussaint bolted the plate into place over the soundboard, and reached once more into his little box of green strings and metal chips to check the bearing. It had been six hours since he had first threaded those strings through the piano, and much had happened to K 2571 in the meantime. I was amazed to see that now, as he threaded them again, they still lay perfectly flat across the bridge. I felt like exclaiming, “It worked!” I recorded this sentiment in my notebook, and when I looked up, Toussaint was bent over another piano.

Two weeks later, as Vahe Fesdjian installed a set of 243 strings on K 2571–one each for the lowest eight notes, two each for the next five, and three each for all the rest–workers on the floor below him prepared the piano’s action, the device that would impart to the strings the energy of the pianist’s fingers. This device is the essence of the piano: when the reference books say that Bartolommeo Cristofori invented the instrument sometime around 1700, they really mean he invented the action. The rest, after all, was just wood and wire, things that could be found on any harpsichord or clavichord.

Before the eighteenth century, stringed keyboard instruments were severely limited–at least in comparison with the modern piano–by the means they employed to excite the strings to vibration. In the harpsichord, the strings were plucked by a quill, an arrangement that gave off the same volume regardless of how firmly the keys were struck. With the clavichord, the player could control the volume of individual notes, but there wasn’t much volume to control. The instrument was small, and its strings were struck with a “tangent,” a small metal blade embedded in the back of each key; the sound it produced was similar in character and volume to a single note on a modern autoharp–if the autoharp is played softly. Another drawback was that the tangent had two functions: in addition to exciting the string, it stopped the string–that is, determined the length of its vibrating section, much as a guitarist or violin player does with his finger. As soon as the clavichordist removed his finger from the key the tone would disappear. A modern piano maker would say that the clavichord had no “carry”

Cristofori’s solution to these problems was the gravicembalo con piano e forte–“harpsichord with soft and loud”–the earliest extant examples of which date back to the 1720s. Though rather basic by modern standards, Cristofori’s action performed all the essential functions of the modern action save one: the “repetition,” which allows a note to be restruck before the key returns to its original position. This may not have been necessary in Cristofori’s time, but later, as piano cases grew stronger and their strings and hammers larger, the touch of the keyboard became deeper and heavier, and players began to find that they could not repeat notes as rapidly as they wanted to. This problem was ultimately solved by a French piano maker, Sebastien Erard, who, in 1821, patented the “double-escapement” action that is the basis for all grand-piano actions made today.

The modern grand action is a marvelously complicated device, a contraption of wood, felt, leather, spring wire, and small bits of metal that must accomplish a bewildering variety of functions simultaneously. First, it must multiply the motion of the key in both speed and distance: the hammer must move farther and faster than the key does. Second, so the hammer will not remain pressed against the strings if the key remains depressed–thus muffling the sound it has created–the hammer must be thrown free from the rest of the action, so that it travels independently over the last fraction of its path and rebounds immediately after striking the strings. Third, the hammer must not bounce back up to the strings with its momentum; the action must catch and hold it as it makes its downward arc. Fourth, because the player will want to restrike a note without waiting for the key to come back up, or without having to lift his finger entirely off the key, the part that propels the hammer must return to its original position, ready to strike again, while the hammer itself and the rest of the action are still in motion. Meanwhile, the damper that has been sitting over the strings, preventing them from vibrating in sympathy with other notes, must be lifted so the strings can sound cleanly, and must fall back promptly to cut off the sound when the key is released–unless the player wants the sound to continue after the key has been released, an eventuality that must also be taken into account. Finally of course, the action must do all this without making the slightest sound of its own.

The modern grand action is a marvelously complicated device, a contraption of wood, felt, leather, spring wire, and small bits of metal that must accomplish a bewildering variety of functions simultaneously. First, it must multiply the motion of the key in both speed and distance: the hammer must move farther and faster than the key does. Second, so the hammer will not remain pressed against the strings if the key remains depressed–thus muffling the sound it has created–the hammer must be thrown free from the rest of the action, so that it travels independently over the last fraction of its path and rebounds immediately after striking the strings. Third, the hammer must not bounce back up to the strings with its momentum; the action must catch and hold it as it makes its downward arc. Fourth, because the player will want to restrike a note without waiting for the key to come back up, or without having to lift his finger entirely off the key, the part that propels the hammer must return to its original position, ready to strike again, while the hammer itself and the rest of the action are still in motion. Meanwhile, the damper that has been sitting over the strings, preventing them from vibrating in sympathy with other notes, must be lifted so the strings can sound cleanly, and must fall back promptly to cut off the sound when the key is released–unless the player wants the sound to continue after the key has been released, an eventuality that must also be taken into account. Finally of course, the action must do all this without making the slightest sound of its own.

Most piano manufacturers buy their actions ready-made from suppliers to the trade. Steinway buys actions for its upright pianos, but all its grand actions are made in the Astoria factory, mostly in two long, narrow rooms on the second and third floors. These rooms are the domain of John Scalera, the action-assembly foreman, who hired on at Steinway shortly after arriving in the U.S. from Italy. He had a cousin who was employed in the mill department. Scalera spends most of his working day walking the aisles of the department, solving problems, answering questions, and peering into the innards of recalcitrant woodworking machines. As he goes, he carries with him the image of a sort of universal pianist–“he”–whose needs define the job and remind him of its importance. Once, as he loaded my cupped hands with the seventeen small wooden parts that go into each note’s action assembly, he told me that most of them wouldn’t be necessary if “he” wanted to play a note only once, but “he” sometimes wants to repeat notes rapidly. Another time, he explained the necessity of the back check, which catches and holds the hammer on its way down, by saying, “See, he doesn’t want a second sound. He wants to play when he feels it’s necessary to play.”

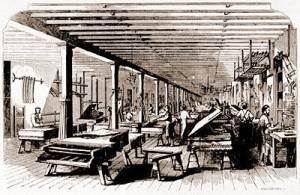

In the action department, the Steinway plant comes closest to the popular conception of what a busy but aging American manufacturing facility looks, sounds, and smells like. In the second-floor room, where wood is cut and machined into the elaborate shapes of the action parts, sawdust hangs constantly in the air, despite an impenetrable tangle of vacuum pipes designed to suck it toward the ceiling and dispatch it to the wood-burning boiler; it is mixed with the smell of lubricating oil and just a touch of the burning odor produced by the friction of automatic knives and saws against wood. The machines emit high-pitched whines as they shape the wood, and parts of them seem to move up and down, in and out, of their own volition, gasping with bursts of air pressure as though they were breathing. In one corner of the room, a woman feeds a slat of wood into one end of a machine and collects several dozen small action parts from the other. In an opposite corner, an automatic tumbler spins continuously, rolling parts against one another to eliminate the tiny splinters and imperfections left by the cutting machines. Next to the tumbler, a woman behind a desk sorts through a pile of parts, occasionally plucking out a reject and discarding it.

In the action department, the Steinway plant comes closest to the popular conception of what a busy but aging American manufacturing facility looks, sounds, and smells like. In the second-floor room, where wood is cut and machined into the elaborate shapes of the action parts, sawdust hangs constantly in the air, despite an impenetrable tangle of vacuum pipes designed to suck it toward the ceiling and dispatch it to the wood-burning boiler; it is mixed with the smell of lubricating oil and just a touch of the burning odor produced by the friction of automatic knives and saws against wood. The machines emit high-pitched whines as they shape the wood, and parts of them seem to move up and down, in and out, of their own volition, gasping with bursts of air pressure as though they were breathing. In one corner of the room, a woman feeds a slat of wood into one end of a machine and collects several dozen small action parts from the other. In an opposite corner, an automatic tumbler spins continuously, rolling parts against one another to eliminate the tiny splinters and imperfections left by the cutting machines. Next to the tumbler, a woman behind a desk sorts through a pile of parts, occasionally plucking out a reject and discarding it.

Directly above the machining room, in a space identical in layout but somewhat more genteel in ambience, workers glue felt to the wood at nearly every point where the parts will meet, to prevent noise in the finished action. At three especially troublesome locations, where the collisions will be particularly high in impact, they apply the skin of a small Brazilian deer to cushion the blows. This skin is especially prized for use in the “knuckle,” the part of the hammer shank that bears the full brunt of the pianist’s enthusiasm. In the early 1970s, when the Brazilian government put a temporary embargo on the export of these skins, Steinway engineers tried replacing them with materials as familiar as cowhide and as exotic as the skin of an African antelope called the kudu; nothing they tried seemed to have the right combination of durability, thickness, and grain structure. They now buy the Brazilian deerskins in year’s-supply lots and keep their fingers crossed.

The action parts are joined by tiny metal pins, each pin constituting a hinge, or “action center,” around which the parts must move freely. A set of eighty-eight finished “repetition” assemblies is then screwed into one side of a metal frame, and a set of eighty-eight independent hammer shanks into the other. Finally the shanks are fitted with felt-covered hammerheads, manufactured in a separate department adjacent to the action rooms. Here again, Steinway departs from conventional practice by making its own hammers, for both grand pianos and uprights. The felt strips and wooden slats from which the hammerheads are made are tapered from one end to the other, with the result that the shape of the hammers changes from the bottom of the scale to the top–from plump, pear- shaped masses of felt to thin, hard, felt-covered sticks. The strings at the treble end of the piano are very short and rigid, and it is difficult to coax much sound from them; the graduation of size and shape in the hammerheads is one of several measures taken to even the responsiveness of the instrument across the scale.

The action parts are joined by tiny metal pins, each pin constituting a hinge, or “action center,” around which the parts must move freely. A set of eighty-eight finished “repetition” assemblies is then screwed into one side of a metal frame, and a set of eighty-eight independent hammer shanks into the other. Finally the shanks are fitted with felt-covered hammerheads, manufactured in a separate department adjacent to the action rooms. Here again, Steinway departs from conventional practice by making its own hammers, for both grand pianos and uprights. The felt strips and wooden slats from which the hammerheads are made are tapered from one end to the other, with the result that the shape of the hammers changes from the bottom of the scale to the top–from plump, pear- shaped masses of felt to thin, hard, felt-covered sticks. The strings at the treble end of the piano are very short and rigid, and it is difficult to coax much sound from them; the graduation of size and shape in the hammerheads is one of several measures taken to even the responsiveness of the instrument across the scale.

K 2571’s action was finished on September 16, when Jorge Nieves inspected and regulated it to ensure that its parts would move the way they were intended to. When he dispatched it to the forefinishing department, to meet the rest of the piano, most of the instrument’s major parts were complete, and things began coming together rapidly. On September 24, Eddie Carrasco matched the action to a set of keys manufactured by Pratt, Read & Company of Ivoryton, Connecticut. (There hasn’t been much ivory coming out of Ivoryton lately; Steinway switched to plastic-covered keys in the 1950s.) Then, in a woodworking operation no less exacting than the bellying job, Carrasco fitted the key-action assembly into the case in a way that accommodated two impossibly contradictory demands. So that the wooden frame on which the keys rested would not clack against the case’s key bed in fortissimo passages, the two surfaces had to fit so snugly against each other that they would act as virtually a single piece of wood. At the same time, the entire key-action assembly had to be able to move about an eighth of an inch toward the treble side of the case when the left, or “soft,” pedal was depressed, so the hammers would strike only two of three unison strings in the three-string notes, and one of two in the two-string notes. Carrasco achieved this miracle by hand-planing the wooden surfaces in a convoluted arrangement of concavities, convexities, and clearances. It was custom work.

When he was finished-when, in the words of his foreman, Tony Fernandez, the action and case were “man and wife”–workers in the grand-finishing department made the union irrevocable by installing wood blocks and hardware around the inside perimeter of the case to hold the action and guide its motion. A couple of days later, the action was reinspected, and any parts that did not move freely enough were taken apart and repinned. On the morning of October 16, K 2571 was wheeled into a sound-proofed room and subjected to the “banger.”‘ an eighty-eight-fingered robot that played a rumbling composition of almost unbearable atonality, striking each key some 10,000 times in a span of forty-five minutes; then Paul Juganaru spent about eight hours fussing with the keys and broken-in action. On October 21, after being tuned for the first time, the piano went to the work station of Earl Baldwin, who made and installed a set of dampers, and from there it went to the rubbing department, where its shiny sprayed-on coat of black lacquer was reduced, largely by hand, to a smooth, dull softness. On November 3, almost nine months after taking shape in the rim-bending room, K 2571 finally looked and worked like a Steinway. Now all that remained was to make it sound like one.

Source: http://www.sherwinbeach.com